- Rotogravure Printing Machine

- Lamination Machine

- Flexo Printing Machine

- Coating Machine

- Slitter Rewinder Machine

- Inspection Rewinding Machine

- Doctoring Rewinding Machine

- Winding Rewinding Machine for Inkjet Printer

- Hydro Pneumo Web Aligner System

- Web Aligner System

- Web Guiding Systems

- Roll Stretch Wrapping Machine

- BOPP Tape Cutting Machine

- Core Cutting Machine

- Edge Guiding Systems

- Tracking Roller Assembly

- Unwinder Machine

- Rewinder Machine

- Folding Open Machine

- Trim Rewinder Machine

Web Aligner System

We have been successfully manufacturing, exporting & supplying all types of Web Aligner System, Web Guiding System, Hydraulic Power Pack Unit, Line Guiding System, etc. since last 25 years from Ahmedabad, Gujarat, India. We are winner of 3 times National Award and 2 times International Award for Quality manufacturing.

KEW is the most leading manufacturer, exporter & supplier for Web Aligner Units in India. We have the capacity to supply 100-150 units of Web Guiding Systems per month. We have systematic work flow chart & updated technology to produce the machine at very high speed and great perfection. We invite inquiries from machinery manufacturers also to purchase the units in bulk orders.

Web Aligner System Video

Web Aligner System Video

Web Aligner System

KEW Manufacturers, exports & supplies Web Aligner System with high production output & efficient edge guiding function with more than 8000 installation in place all over India and overseas like Saudi Arabia, UAE, Dubai, Sharjah, South Africa, Nigeria, Ghana, Congo, Kenya, Zambia, Sri Lanka, Bangladesh, Malaysia, Pakistan, Nepal, Russia, Thailand, Indonesia, Brazil, Colombia, Venezuela, Argentina, Mexico, Canada, etc. making us the biggest manufacturer, exporter & supplier of Web Guiding System.

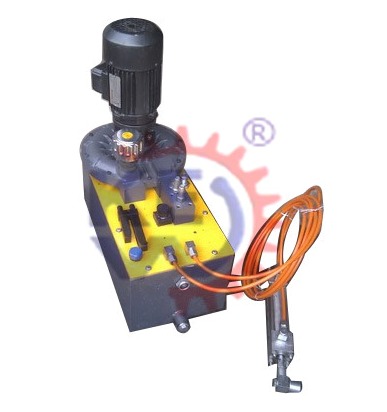

KEW make Hydro–Pneumatic Web Aligner are the Heart of Hydro Pneumatic web guiding system, Web Aligner Manufacturer to automatically guide all type of material of any width, at any speed, under any load. Completely self-contained with an integral air generator for the sensor. It is coupled with 3 phase AC motor and the Hydraulic pump is also attached to the same shaft which is fitted inside the oil tank filled with Hydraulic oil. The signals from the Air flow sensors are received by spool type proportional servo valve mounted just under the polyester diaphragm. Unique design gives extremely narrow dead band & fastest possible response for un-excelled guiding results. The power pack units are available in different models from 0.25 HP to 3 HP to meet any guiding application you may have. inbuilt Air Generator avoids the use of external air supply.

These units are used to automatically guide all type of flexible materials of any width, at any speed, under any load. Inherent

KEW Hydraulic Power Pack units are used to automatically guide all types of flexible materials of any width, at any speed, under any load. Completely self-contained, with an integral air pump, these units eliminate the need for additional air regulators or plant air. Modular construction and sub plate-mounted components provide maximum ease of servicing. Inherent capabilities of KEW Web Guiding System assure stable operation at all correcting speeds and loads. Air Pressure Power Units are available in models from 1/4 H.P. to 3 H.P. to meet any guiding application you may have. Double and triple power units are available incorporating two and three servo valves on the same reservoir to handle multiple guiding applications. A source of power is mandatory in a web guiding system. The Hydraulic Power Pack unit is much more than just an energy source, however, because it normally furnishes modulated power to the actuating devices. It, therefore, is an amplifier of control signals, as well as a power source In addition to providing hydraulic power for the actuating circuit the power unit produces pneumatic power for the sensors. Sensor supply pressure must remain constant, and the power supply provides this element. Our constant pressure generator produces constant pressure at a given head no pressure regulator is therefore required. Water, oil and scale contamination and other miscellaneous plant air problems are also avoided.

KEW uses one of a series of Web guide pneumatic hydraulic units in most of its systems. These units come in several sizes and a suitable one can be found for any application. Our Pneumo Hydraulic Power Pack Units are perfectly manufactured with optimum air flow and maximum load capacity.

Krishna Engineering Works manufactures, exports & supplies Web Aligner Units with efficient edge guiding function with more than 7000 installation in place all over India and overseas like Saudi Arabia, UAE, Dubai, Sharjah, South Africa, Nigeria, Ghana, Congo, Kenya, Zambia, Sri Lanka, Bangladesh, Malaysia, Pakistan, Nepal, Russia, Thailand, Indonesia, Brazil, Colombia, Venezuela, Argentina, Mexico, Canada, etc.

Web - Aligner (Power Pack) Unit Complete With:

- 0.5 H.P. Motor

- Air Pipe - 5 Mtr.

- Oil Pipe - 5 Mtr.

- Sensor - 1 pcs

- Adjuster - 1 pcs.

- Air Filter - 1 pcs.

- Oil Filter - 1 pcs.

- Hydraulic Cylinder size 4”, 6” & 8”strock - 1 pcs.

SENSORS:

In the specially designed non-contact Air flow sensors, air is expelled from two opposing orifices. The differential air pressure is use to detect lateral wandering of the material in process. The Airflow sensors are self cleaning & fitted with fine adjustment mounting bracket.

HYDRAULIC CYLINDER:

It works on hydraulic pressure. It actuates the correcting frames. Available in different size from 2" to 18" stroke length.

Technical Specifications for Power Pack Unit:

TYPE |

KEW–17 |

KEW–30 |

Motor rating (3 phase, 50 Hz) |

0.5 HP |

1HP |

Pump flow rate |

3.4 l/min |

5.8 l/min |

Tank capacity |

17 liters |

30 liters |

Oil type |

Servo 32, Enklo 44, Hydro 37 |

|

Line pressure |

14 bar |

21 bar |

Max. Operation force (50.8 mm dia. Cylinder) |

260kg |

389.5 kg |

Follow-up speed |

|

|

Max. At 3.4 l/min |

30mm/sec |

-- |

At 5.8 l/min |

-- |

40mm/sec |

Air sensor air pressure |

5 to 28 mbar, infinitely adj. |

|

Weight including oil |

40kg |

60kg |

Double Power Pack

Dual Web Aligner

We are skilled in offering the Double Power Pack renowned for providing high capacity, control options & configurations to be utilized in almost any application. The Double Power Pack is designed and manufactured using premium quality hydraulic components selected from a wide range and assembled using high technology systems which are designed with technologically advanced concept.

Electro-Hydro Web Aligner Unit

Benefits of Electro-Hydro Web Aligner Unit:

- No maintenance

- Labor saving

- Electricity saving

- No wastage

- More production

STRUCTURE OF THE WEB ALIGNER

- M. S. Tank and M. S. Plate

SYSTEM OF THE OPERATION IN RUNNING OF ELECTRO-HYDRO WEB ALIGNER

- Electronic of the film Photocell sensor for edge.

- Electronic 0 – 5 HP AC Motor.

- Electrical Panel Board for Operate the complete Unit.

- Hydraulic Cylinder – Adjuster – Oil Pipe.

TECHNICAL DATA

- Speed of Unit 250/min

- Variation of the film Winding is 0.5

Suitable for all types of Machines like:

- Rotogravure Printing Machine

- Lamination Machine / Coating Machine

- Slitter Rewinder Machine

- Doctoring Rewinding Machine

- Paper Machinery

- Textile Machine like Batching Machine, Inspection Rewinding Machine , etc

- Tyre-Cord Machinery

Web Aligner System Video

Web Aligner System Video

- Rotogravure Printing Machine

- Lamination Machine

- Flexo Printing Machine

- Coating Machine

- Slitter Rewinder Machine

- Inspection Rewinding Machine

- Doctoring Rewinding Machine

- Winding Rewinding Machine for Inkjet Printer

- Hydro Pneumo Web Aligner System

- Web Aligner System

- Web Guiding Systems

- Roll Stretch Wrapping Machine

- BOPP Tape Cutting Machine

- Core Cutting Machine

- Edge Guiding Systems

- Tracking Roller Assembly

- Unwinder Machine

- Rewinder Machine

- Folding Open Machine

- Trim Rewinder Machine

- Rubber Roller

- Industrial Roller

Awards

Our company is well experineced in Flexible Packaging & Converting Field. We are Manufacturing, exporting and supplying Rotogravure Printing Machine, Lamination Machine, Flexo Printing Machine,Coating Machine, Slitter Rewinder Machine, Inspection Rewinding Machine, Doctoring Rewinding Machine, Winder Rewinder Machine for Inkjet Printer, Hydro Pneumo Web Aligner System, Web Aligner System,Web Guiding Systems,Roll Stretch Wrapping Machine, BOPP Tape Cutting Machine,Core Cutting Machine, Edge Guiding Systems,Tracking Roller Assembly,Unwinder Machine,Folding Open Machine,Rewinder Machine. The company is providing such a high quality machinery and service..

view more

KRISHNA ENGINEERING WORKS

Punit Nagar Crossing Road, Ghodasar,

Ahmedabad-380050, Gujarat, INDIA

Tele-Fax : +91-79-40085305

Email : krishnaengineeringworks@yahoo.com

kewinquiry@gmail.com

Website : www.krishnaengineeringworks.com

Manufacturer, Exporter, Supplier