- Rotogravure Printing Machine

- Lamination Machine

- Flexo Printing Machine

- Coating Machine

- Slitter Rewinder Machine

- Inspection Rewinding Machine

- Doctoring Rewinding Machine

- Winding Rewinding Machine for Inkjet Printer

- Hydro Pneumo Web Aligner System

- Web Aligner System

- Web Guiding Systems

- Roll Stretch Wrapping Machine

- BOPP Tape Cutting Machine

- Core Cutting Machine

- Edge Guiding Systems

- Tracking Roller Assembly

- Unwinder Machine

- Rewinder Machine

- Folding Open Machine

- Trim Rewinder Machine

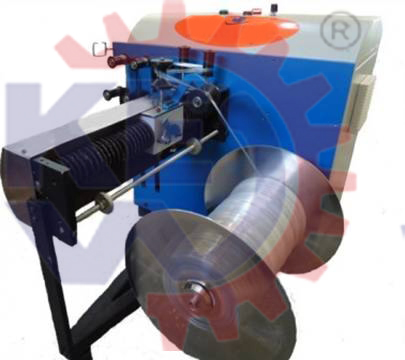

Trim Rewinder Machine

| Technical Specification |

| Krishna Engineering Works Trim winders incorporate many features for high reliability of trim winding. The precision electromechanical traversing system is maintenance free with operator control of the traversing rate which remains constant regardless of the line speed or the spool diameter. This, together with the inbuilt pineapple winding technology, ensures optimum winding of the trim and therefore increases the reliability. The lightweight web guide roll assembly traverses for high-speed operation with the spool running in a fixed position. |

| Each trim winder is driven by its own variable speed motor running under closed loop tension control from a precision dancer. |

| Alternatively, where space is at a premium, the winder motor can be operated under direct torque control. Full sized rolls can be unloaded quickly and the winder restarted. Winders are fitted with a remote air inflation system on winding shafts, Air Shaft for paper cores or a quick release mechanism on shafts. |

Trim Rewinder Machine

| Standard Features | Optional | ||||||||||||||||||||||||||

|

|

Trim Winder Typical Specification

| Trim Width | 5 to 60 mm |

| Web Thickness | 10um to 1mm |

| Package Diameter | 350 mm |

| Package Width | 350 mm |

| Core Diameter | 100 mm |

| Maximum Speed | 500 m/min |

| Operation |

| The motion control drive is controlled by a digital inverter drive, capable of both driving and stopping the motor. The material is fed by a dancer for tension control, equipped with a position feedback through the ultrasonic sensor. Together with the PID controls on the trim winder control board, this provides a speed reference for the motion control drive. The system operates to maintain the dancer in a fixed position, thus providing static rewinding tension. |

| The tension is set by the position of the dancer. When the dancer is close to the reference, the trim tension is high. When it’s furthest away from the reference, the tension is low. Dancer position is set by the internal set tension in torque mode. The dancer is mounted on a cross travel mechanism and acts as a layering guide to the trim. |

| The cross travel is controlled by lead motion linear guide ways with automatic and reversing, so that dancer always rotates in motion control. The traverse motor is controlled by a digital inverter drive operating directly from the AC supply. A set point isolator on the control board links the winding motor speed reference with the traverse motor so that they operate in unison. |

| The winder can either be stopped and started from the remote control push buttons or linked directly to the main feed machine. A trim break detector on the control operates three seconds after start up to stop the winder if the dancer hasn't been pulled off its end stop position. |

- Rotogravure Printing Machine

- Lamination Machine

- Flexo Printing Machine

- Coating Machine

- Slitter Rewinder Machine

- Inspection Rewinding Machine

- Doctoring Rewinding Machine

- Winding Rewinding Machine for Inkjet Printer

- Hydro Pneumo Web Aligner System

- Web Aligner System

- Web Guiding Systems

- Roll Stretch Wrapping Machine

- BOPP Tape Cutting Machine

- Core Cutting Machine

- Edge Guiding Systems

- Tracking Roller Assembly

- Unwinder Machine

- Rewinder Machine

- Folding Open Machine

- Trim Rewinder Machine

- Rubber Roller

- Industrial Roller

Awards

Our company is well experineced in Flexible Packaging & Converting Field. We are Manufacturing, exporting and supplying Rotogravure Printing Machine, Lamination Machine, Flexo Printing Machine,Coating Machine, Slitter Rewinder Machine, Inspection Rewinding Machine, Doctoring Rewinding Machine, Winder Rewinder Machine for Inkjet Printer, Hydro Pneumo Web Aligner System, Web Aligner System,Web Guiding Systems,Roll Stretch Wrapping Machine, BOPP Tape Cutting Machine,Core Cutting Machine, Edge Guiding Systems,Tracking Roller Assembly,Unwinder Machine,Folding Open Machine,Rewinder Machine. The company is providing such a high quality machinery and service..

view more

KRISHNA ENGINEERING WORKS

Punit Nagar Crossing Road, Ghodasar,

Ahmedabad-380050, Gujarat, INDIA

Tele-Fax : +91-79-40085305

Email : krishnaengineeringworks@yahoo.com

kewinquiry@gmail.com

Website : www.krishnaengineeringworks.com

Manufacturer, Exporter, Supplier

Manual Slitting Rewinding Machine

Manual Slitting Rewinding Machine